What are the 5Es in Safety and Why Are They Essential for Workplace Safety?

When it comes to workplace safety, there are various tools and strategies that organizations use to ensure their employees' safety and well-being. One such tool is the '5Es' in safety. But what is 5Es in safety, and why is it crucial for ensuring workplace safety? In this blog post, we'll take a deep dive into the 5Es in safety and explore how they can be used to improve safety practices in your workplace. So, if you're ready to learn more about this essential safety framework, keep reading!

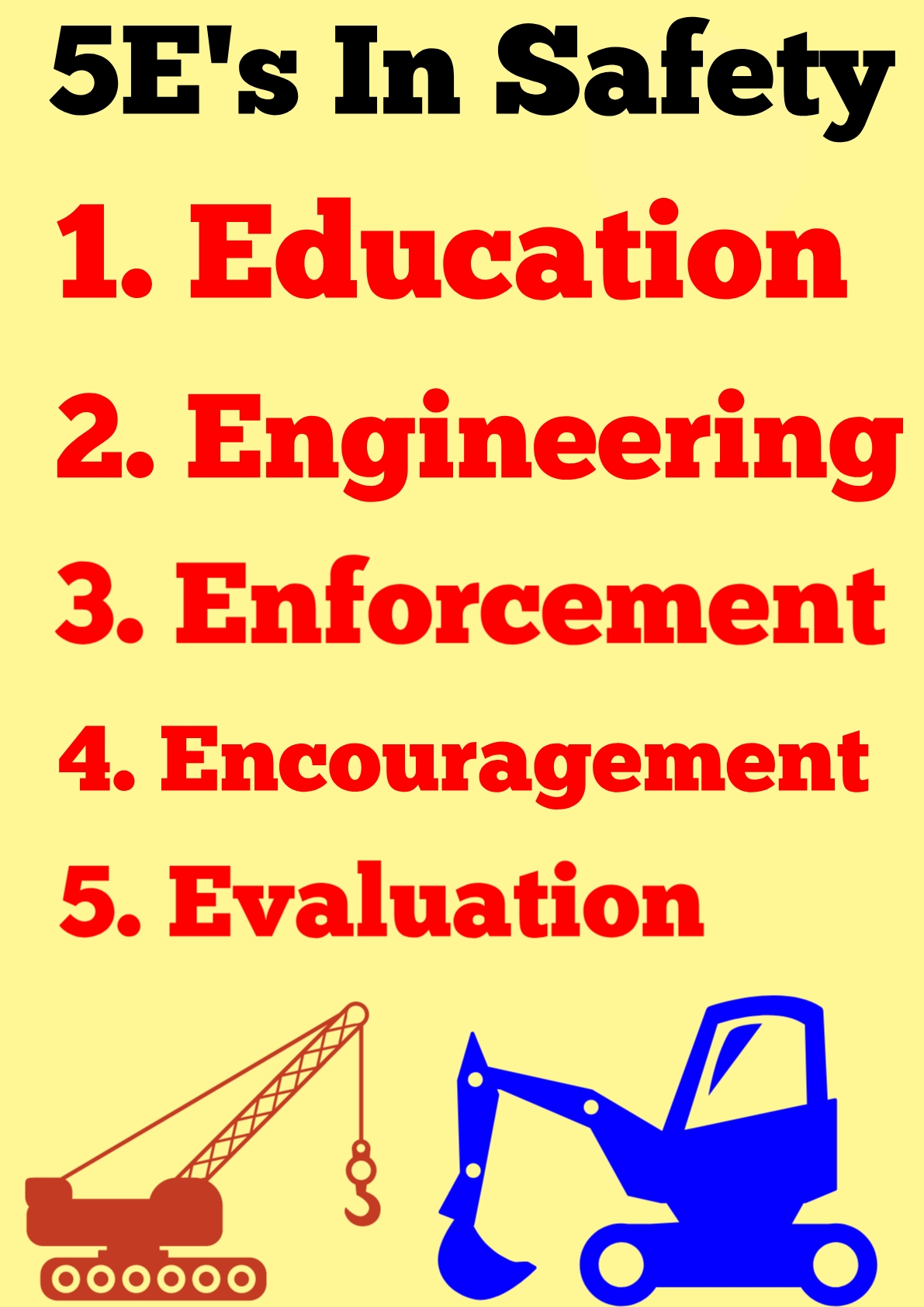

What are '5Es' in safety?

The '5Es of safety' are a framework that businesses and organizations use to promote safety in the workplace. This model is widely recognized as an effective method of accident prevention and has been used successfully in various industries. The 5Es represent five essential elements that must be implemented to achieve a culture of safety in any workplace. These five elements are education, engineering, enforcement, ergonomics, and evaluation. Each E is equally important, and when applied effectively, they work together to create a comprehensive approach to workplace safety. (You are reading What Are the 5Es in Safety)

|

| What are the 5Es in Safety and Why Are They Essential for Workplace Safety? |

Why the 5Es are essential for workplace safety

The 5Es of accident prevention are critical for ensuring that your workplace is a safe and secure environment. Each E plays a crucial role in promoting a safety culture that can help prevent accidents from occurring. When all five of the 5Es are in place, workers are less likely to get injured, and the risk of property damage and lost productivity is minimized.

Without proper safety measures in place, companies put themselves at risk of losing their reputation, facing regulatory fines and penalties, and ultimately hurting their bottom line. The 5Es provide a framework for creating a culture of safety that can protect workers and the business as a whole.

In the following sections, we will discuss each of the 5Es in detail and explore how they work together to create a comprehensive safety plan. By implementing these measures, businesses can help protect their workers, improve their overall safety record, and create a safer work environment for everyone.

All Five Elements of 5Es in Safety: -

1. Education2. Engineering

3. Enforcement

4. Encouragement

5. Evaluation

|

| 5Es in Safety |

First E - Education

Education is the first of the 5Es of accident prevention. This 'E' is focused on providing workers with the necessary information, training, and resources to recognize hazards and respond accordingly. By educating employees about safety procedures and risks, organizations can help reduce the likelihood of workplace accidents and injuries. (5Es of safety)

Education starts from day one of employment, with onboarding programs designed to ensure new employees are aware of the safety risks and protocols. Employers must provide ongoing safety training to their employees to ensure they are aware of the risks and understand the necessary steps to stay safe. This education should include information on potential hazards, how to properly use tools and equipment, and how to handle and dispose of hazardous materials.

Moreover, employers should ensure that safety procedures are well-communicated and easy to follow. Signs, labels, and warning tags can help employees recognize potential dangers and make informed decisions to stay safe. It's important to create a safety culture where workers are empowered to raise concerns and share safety suggestions.

By prioritizing education, organizations can ensure that all workers have the knowledge they need to recognize risks and protect themselves from harm. Education is the foundation of a strong safety culture, and it is an essential part of the 5Es of accident prevention. (You are reading What Are the 5Es in Safety)

Second E - Engineering

Engineering refers to the use of technical solutions to eliminate or control workplace hazards. It involves designing or modifying equipment, machinery, processes, and systems to reduce the likelihood of workplace accidents and injuries. In this way, engineering is a critical aspect of ensuring a safe work environment for employees.For example, an engineering solution for reducing the risk of falls in the workplace might be the installation of guardrails, handrails, and non-slip flooring. Another example could be the installation of automatic shut-off systems on machinery to prevent worker injuries from accidental start-up or entanglement.

Some other examples of engineering solutions include:

- Enclosing hazardous equipment to prevent exposure to dangerous chemicals or radiation

- Installing proper ventilation to reduce exposure to toxic substances

- Replacing manual labor with machinery to reduce the risk of repetitive stress injuries

- Using safety harnesses or nets for workers operating at heights

The engineering aspect of the 5Es is crucial because it focuses on finding ways to eliminate or minimize hazards that can cause injuries or illnesses. By designing work processes and equipment with safety in mind, engineering solutions reduce the chances of accidents and increase workplace safety.

It's important to note that the responsibility for implementing engineering solutions rests with the employer. They should work closely with engineers and safety professionals to identify and assess hazards, and design engineering solutions that effectively address those hazards.

Overall, engineering solutions play a crucial role in workplace safety. The implementation of proper engineering solutions helps protect workers from workplace accidents and illnesses. When combined with the other 5Es - Education, Enforcement, Ergonomics, and Evaluation - engineering ensures a comprehensive approach to workplace safety that can prevent accidents, reduce injuries, and save lives. (You are reading What Are the 5Es in Safety)

Third E - Enforcement

Enforcement is an important aspect of workplace safety, as it ensures that safety policies and procedures are being followed. This E refers to the legal and regulatory measures that are put in place to enforce safety in the workplace. These measures may include safety inspections, audits, and investigations.Enforcement helps to hold employers accountable for ensuring the safety of their workers. Employers who do not comply with safety regulations can face fines, penalties, and legal action. This not only protects workers, but also encourages employers to take safety seriously and invest in the necessary resources and training to maintain a safe work environment.

Employees also play a role in enforcement by reporting any safety concerns or violations to their supervisors or safety representatives. It is important for employees to feel comfortable speaking up about safety issues, and for employers to listen and take action to address them.

In summary, enforcement is a crucial component of workplace safety, as it ensures that safety policies and procedures are being followed and holds employers accountable for providing a safe work environment. Employers and employees both play a role in enforcement, and it is important for everyone to take safety seriously and work together to maintain a safe workplace. (You are reading What Are the 5Es in Safety)

Fourth E - Ergonomics

Ergonomics is all about ensuring that the workplace is designed and organized in such a way as to reduce the risk of injury and promote overall worker well-being. This involves assessing things like workspace layout, equipment, and tools, as well as ensuring that workers are trained to use them in a way that reduces the risk of injury.One of the key principles of ergonomics is that the workplace should be designed around the needs of workers, rather than forcing workers to adapt to the workplace. This means taking into account factors like physical limitations, posture, and range of motion when designing workspaces and choosing equipment.

For example, ergonomics might involve choosing adjustable workstations that can be adapted to accommodate workers of different heights, or investing in ergonomic chairs or standing desks that help workers maintain good posture and avoid back pain. It might also involve choosing tools and equipment that reduce the risk of repetitive stress injuries or designing workflows that minimize the need for workers to lift heavy objects.

Overall, by focusing on ergonomics as one of the '5Es' of safety, employers can help create a safer and more comfortable workplace that reduces the risk of injury and promotes better physical health and well-being for all employees.

Fifth E - Evaluation

The final 'E' in workplace safety is Evaluation. This is the process of analyzing and assessing the effectiveness of your safety program. By evaluating the program, you can identify areas that need improvement, identify potential hazards and risks, and create action plans to address them.Evaluation can be done through various methods, including incident investigations, audits, and inspections. Regular evaluations are essential to ensuring the ongoing effectiveness of your safety program, as well as demonstrating your commitment to safety to your employees. (You are reading What Are the 5Es in Safety)

When conducting evaluations, it's important to involve employees and management, as they can provide valuable feedback on the program. Evaluations should also include a review of the safety policies, procedures, and training programs to ensure that they are up-to-date and aligned with industry standards and regulations.

It's important to note that evaluation should not just be done after an incident or accident occurs. Regular evaluations can help prevent incidents from occurring in the first place by identifying potential hazards and addressing them before they become a problem.

.jpg)

.png)

.png)

0 Comments