Types of Machenical Isolation.

What is Isolation?

Isolation is a method of sperating or blocking the flow of hazardous energy (chemical, gas) in a system or equipment by using blind, closing valve, removing spool section etc.

By the safety point of view it is important to do isolation before working on any equipment to prevent injury or harm due to contact with hazardous material flowing in the equipment or system.

Types of Machenical Isolation:-

- Primary Isolation

- Positive Isolation

What is primary Isolation?

- Primary Isolation is for low risk activity such as replacing pressure guage, filter etc.

- Primary Isolation is the first stage of positive Isolation.

- Single valve block.

- Double valve block.

- Double valve block & bleed.

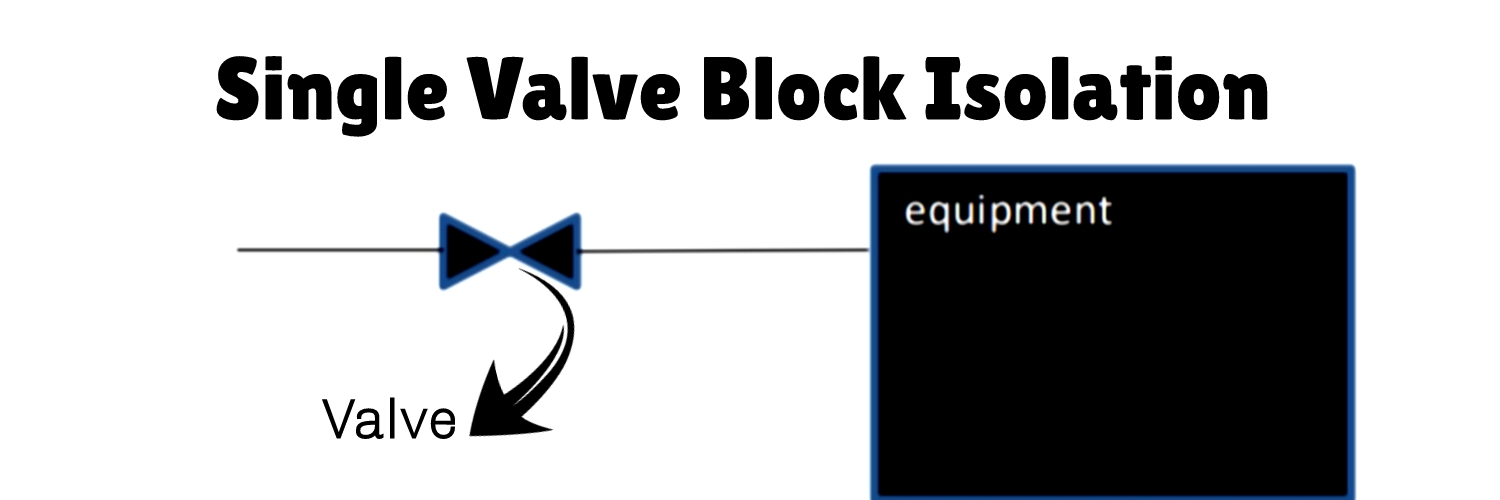

What is single valve isolation?

Isolation by closing a single valve in an equipment is known as single valve block isolation.

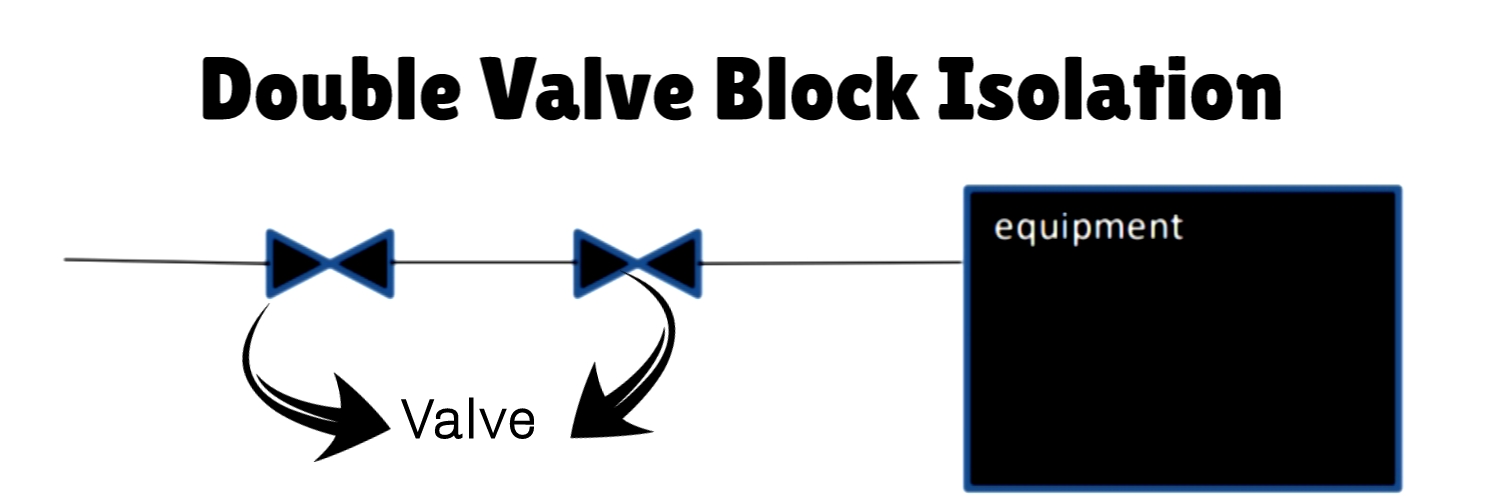

What is Double valve block isolation?

Isolation by closing two valves in a series of an equipment is known as double valve block isolation.

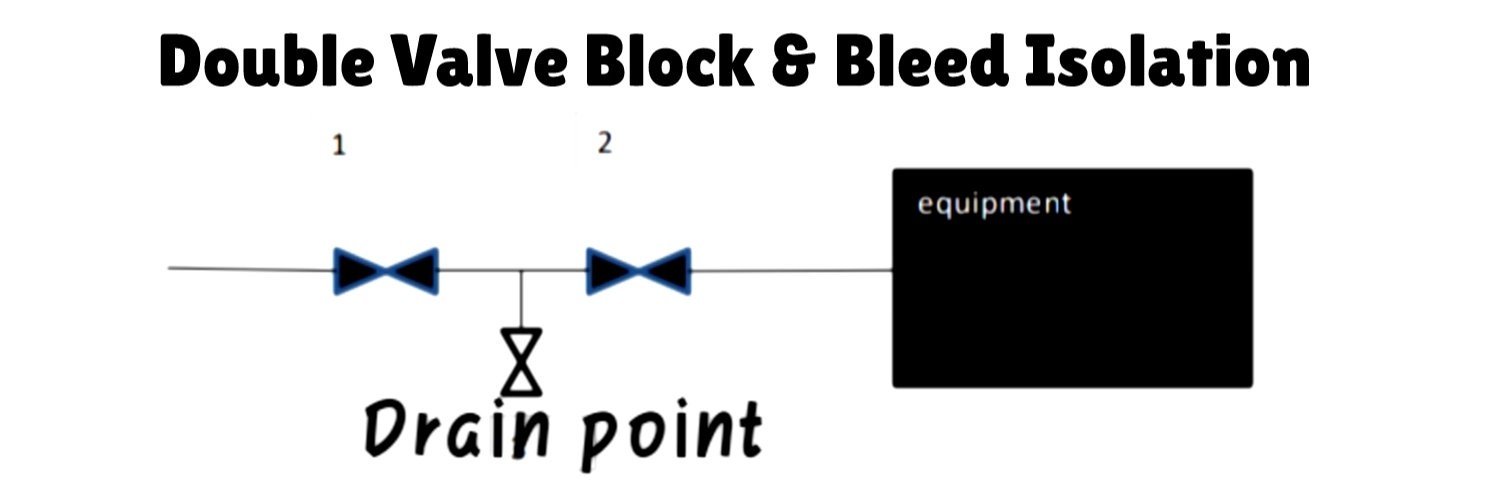

What is Double valve block & bleed isolation?

In double valve block & bleed isolation, two valve closed in a series and chemical drain from the drain point between the two valves of an equation.

What is Positive Isolation?

Positive Isolation is safe then primary isolation, isolation done by blind or spool removal is known as positive isolation, positive isolation mostly use for high risk activity such as confined space entry, cutting of process line etc.

Types of Positive Isolation:-

- Blinding

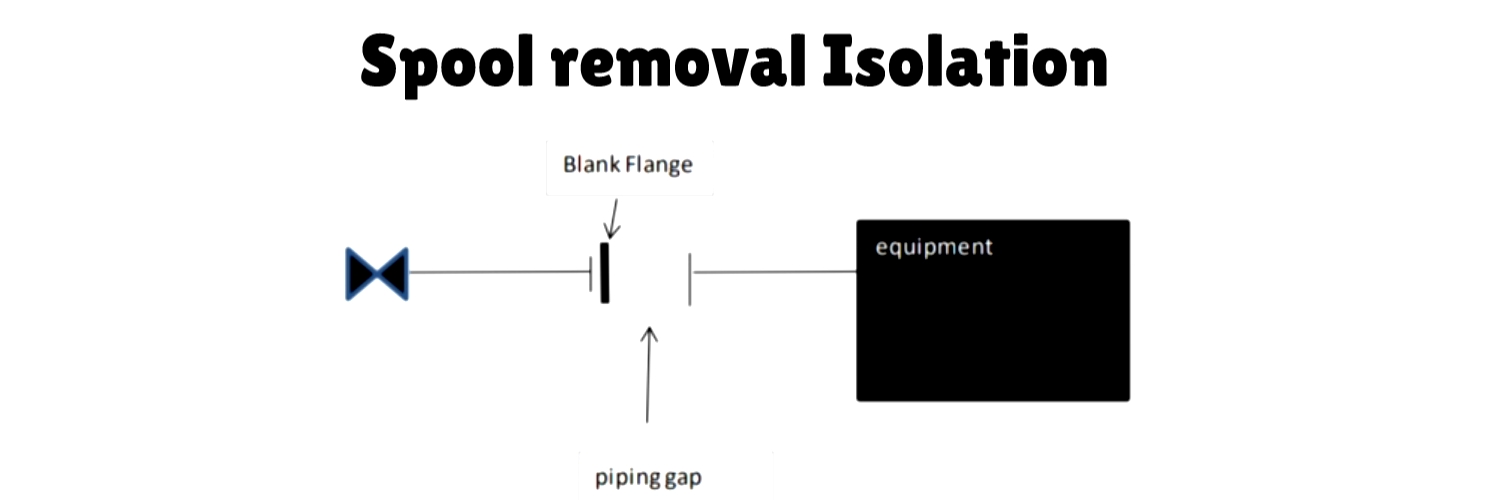

- Spool removal/physical separation/blank

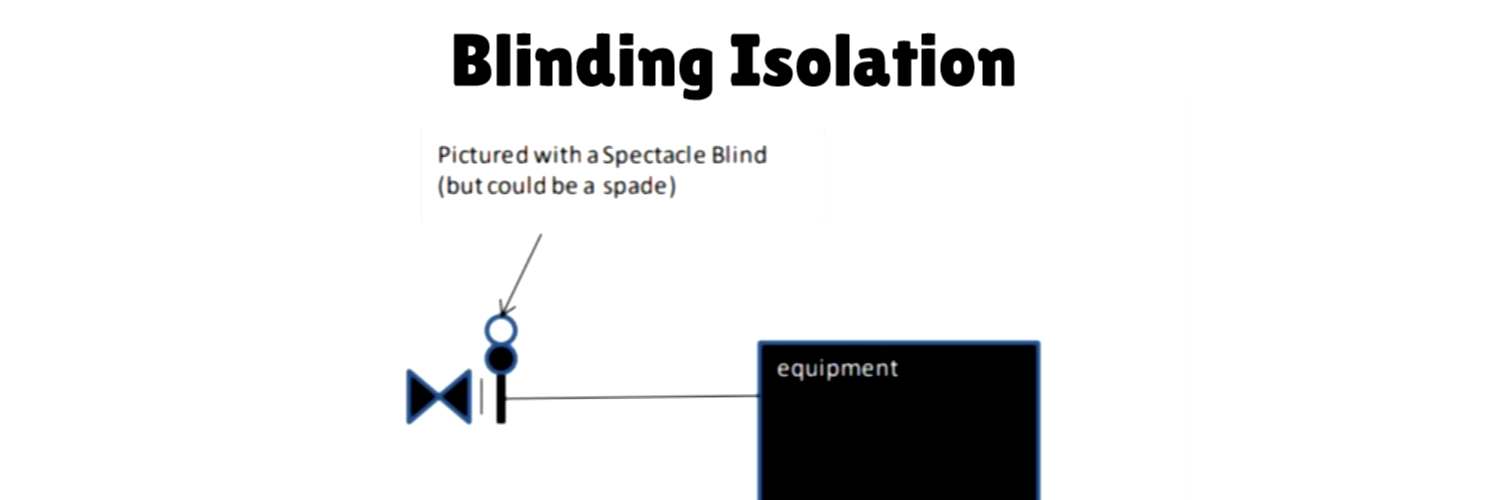

What is Blinding isolation?

Isolation done by inserting blind between flanges is known as blinding.

What is spool removal isolation?

What is Blinding?

Inserting blind between flanges to stop the flow of hazardous energy is called blinding.

What is blind?

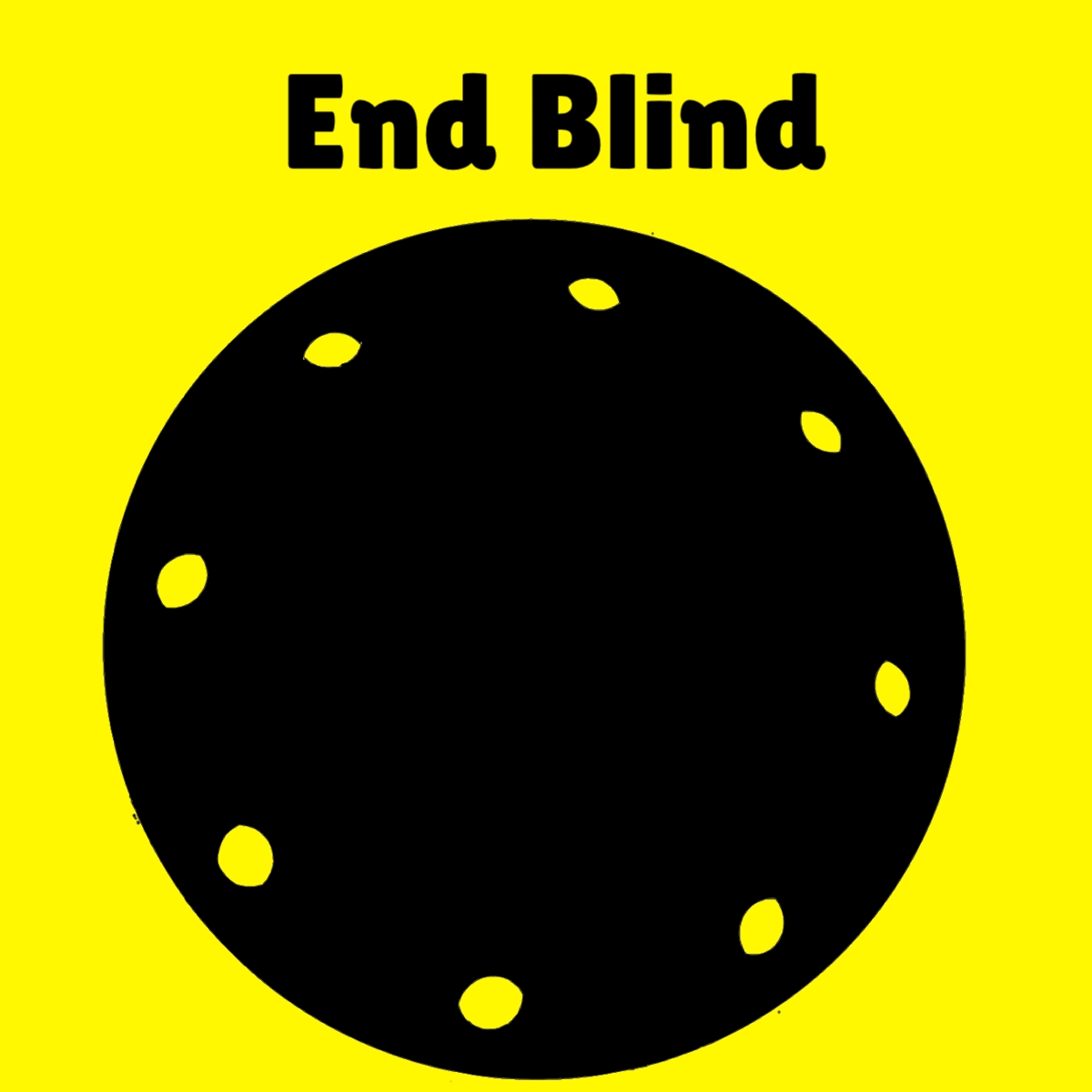

Blind is a metal sheet use to insert between flanges to stop the flow of hazardous energy.

Types of Blind?

- Slip blind / Slip Plate /Spade.

- Spectacle Blind / figure of eight.

- End blind.

Conclusion

FAQ's

How many types of Isolation?

There are mainly two types of Isolation Primary & Positive Isolation and there are three types of primary Isolation and two types of positive Isolation.

Which machenical isolation is more safe?

Positive Isolation especially spool removal or blank isolation is safest isolation.

Where positive Isolation used in Oil & Gas industry?

Positive Isolation is used for confined space entry and cutting of process line in Oil & Gas industry.

Which blind is used most in Oil & Gas plant?

Slip or Spade blind used mostly in Oil & Gas refinery.

Why positive Isolation done?

Positive Isolation is to stop the flow of hazardous energy in the equipment while working on equipment for maintenance.

.jpg)

.png)

.png)

0 Comments